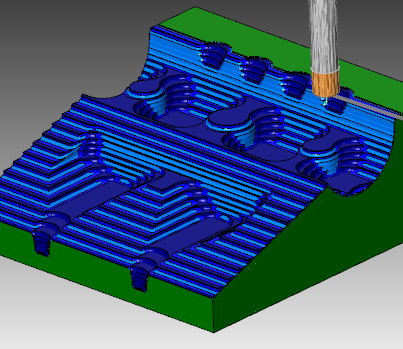

Using Advance Rough with our V25 Mill Pro software you have the option to perform rest roughing. This option allows you to define the previous tool information, allowing you to target left over material that needs to be cleaned up. You can tell when there is material left over by using the analysis tool in our simulation to perform a color scale deviation report.

The deviation is a material offset compared to the target geometry. The color of the material changes the more or less material exists on top of the target geometry. With this feature, the user can identify the amount of the material left on the target geometry;  identify the gouges, when too much material was removed and the target geometry is being damaged; and identify the area where a rest machining is necessary.

identify the gouges, when too much material was removed and the target geometry is being damaged; and identify the area where a rest machining is necessary.

In this picture you can see, in blue and light blue, that there is material left over that needs to be cleaned up.

Using the rest rough option you can target just this material, eliminating wasted tool motion and decreasing your run times.