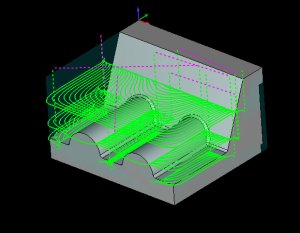

Using the V25 Pro Mill tool path you have more options for cutting parts in 3D.

To start with your stock boundary is used as an open boundary that the tool can pass though. Using the same cutting parameters as the previous example with our advance rough, we get a more efficient tool path, that starts off the part works it’s way in and has smooth cutting motion. Eliminating the need to ramp into the part and allowing for faster cutting speeds. Just based on the tool motion alone you could 2X you speeds and get this job off your bench that much faster.

In additional the machine flat land option when checked will automatically identify flat areas of your part and machine them. Clearing stock that would have been left behind by our standard z level rough routine.

In additional the machine flat land option when checked will automatically identify flat areas of your part and machine them. Clearing stock that would have been left behind by our standard z level rough routine.

You need to spend time to get to know your BobCAD CAM software and all the options it offer you. Take our online classes and speed up the learning curve, allowing you to get more out of your software!