CAD-CAM technology is the modern solution to CNC machining automation. Can your machine shop benefit from CAD-CAM? More often than ever before machine shops are using multiple CNC programming systems than ever before. The reason is simple. Not many CAD-CAM products do it all and small to mid-sized machine shops can benefit from having a primary system with a supporting cast of programming solutions in order to meet all of their programming needs. How can BobCAD-CAM fit the bill as your primary CAD-CAM solution?

CAD-CAM Technology Gives You an Edge

CAD-CAM Technology Gives You an Edge

BobCAD-CAM software has been inside of machine shops for more than 25 years as a solution to automating the part making process for CNC machining. CAD data is needed in order to program toolpath. In today’s manufacturing engineering solid models are primarily used. BobCAD-CAM provides CAD importing as well as full solid modeling functionality so that manufacturers can either import their part models for programming or design them from scratch. This allows shops to easily access CAD parts or make them easier inside of BobCAD-CAM. CAD Design features include drawing with wireframes, surfaces and solids.

2D & 3D Machine Toolpaths for CNC Programming

2D & 3D Machine Toolpaths for CNC Programming

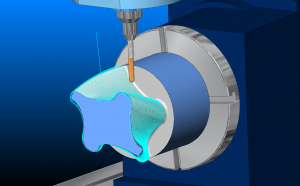

BobCAD-CAM is a modular system. This means that shops that only need 2.5 Axis machining do not have to pay more for features that aren’t needed. The software can be used for Hole Drilling, 2.5, 3, 4 & 5 Axis. Adding machining functionality is easy and affordable. Profiling, pocketing, 3D Semi-Finishing, 3D Finishing and special REST machining toolpaths machining operations with a host of customizable features make machining simple while using the Wizards. Wizards step the operator through the process of programming while removing the guesswork from the entire process. Dynamic Machining Strategies® allow you to use multiple machining strategies for a single CAD feature on a model. This streamlines the setup process by automatically adding the appropriate fields to the Wizard and making sure nothing is missed. This also cuts down overall programming time.

CNC Machine Simulation & Post Processing

CNC Machine Simulation & Post Processing

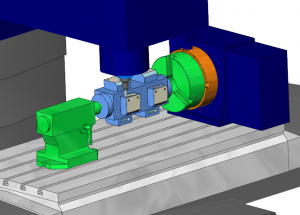

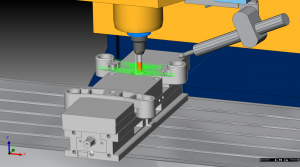

BobCAD-CAM adds the benefit of simulation and customizable machine post processing. Simulation gives you the ability to visualize machining to inspect and eliminate potential mistakes. The Machine Simulation Pro module allows you to use your machine kinematics to simulate the process with the machine you have. This is highly beneficial. When it comes to posting the software can post out to Milling, Lathe, Router, Water Jet, Laser, Burning and Plasma CNC machines. This means that essentially, you only need one BobCAD-CAM for multiple CNC machines on your shop floor. This can not only save money but it can speed up productivity as well.

With so many productivity enhancing benefits, the BobCAD-CAM software is a great product to implement into your CNC manufacturing process.

The pictures perfectly explain tool paths, simulation & post processing of CNC machines. Attractive!